Profile: Kenoteq

Scottish cleantech company Kenoteq has steadily established itself as one of the UK’s most forward-thinking materials manufacturers. Its K-BRIQ is an ultra-low-carbon masonry brick made almost entirely from recycled construction and demolition waste, and is now moving from research to widespread adoption.

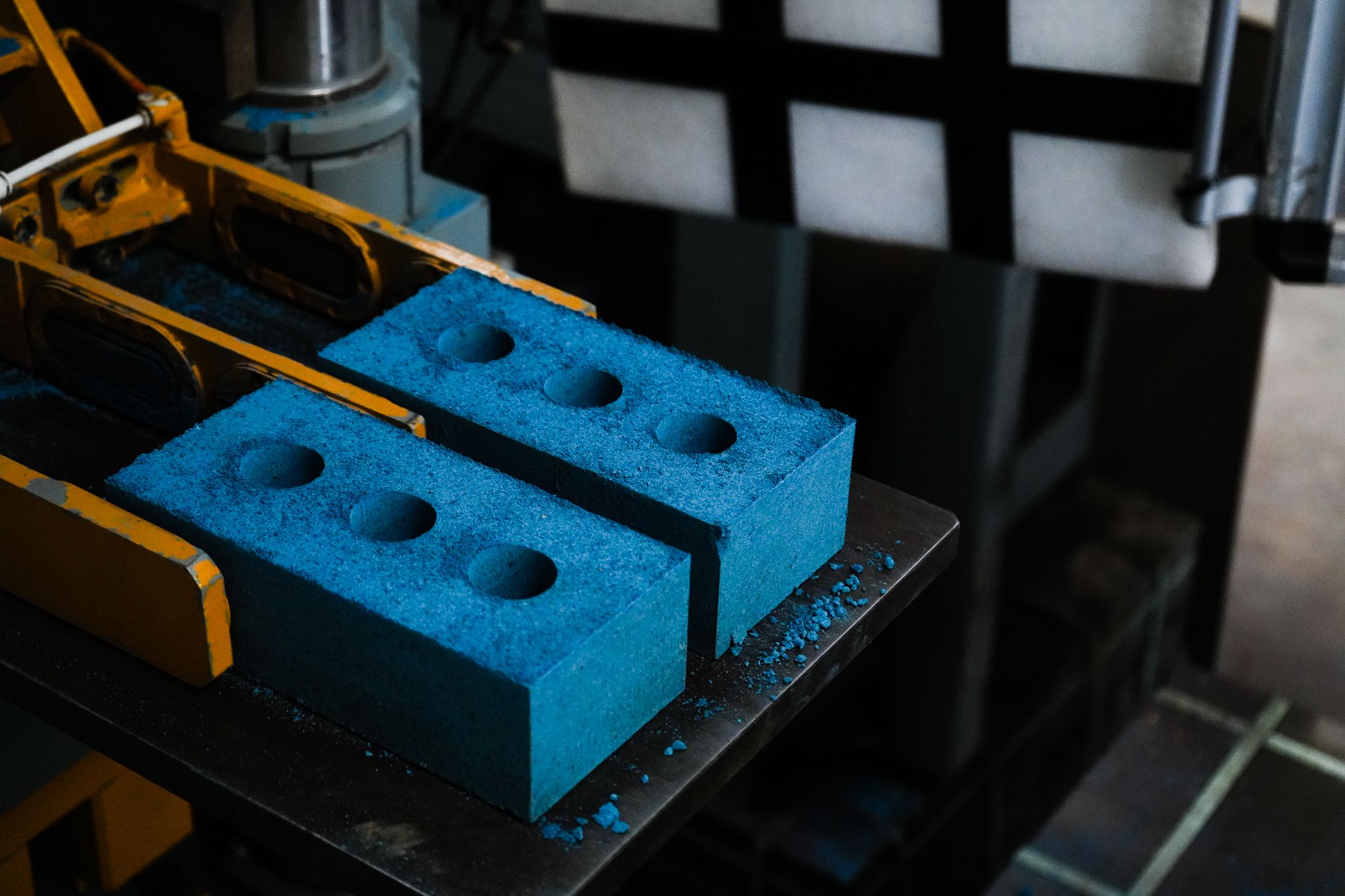

Developed over more than a decade at Heriot-Watt University, the K-BRIQ represents a practical response to two of constructions biggest environmental pressures: embodied carbon and material waste. Each brick is unfired, made from nearly 100% recycled material, and produces 95% less embodied carbon than a conventional clay brick.

At Kenoteq’s East Lothian facility, the company now produces around two million K-BRIQs a year, with capacity to double output as demand grows. Plans are underway to replicate the model through regional production hubs, both in the UK and abroad, using local waste sources to reduce transport emissions and strengthen circular supply chains.

The K-BRIQ has also achieved British Board of Agrément (BBA) certification, confirming its performance in strength, durability, and fire resistance, and enabling it to be specified for use across a broad range of structural and architectural applications. The product achieved the highest durability classification and an A-class fire rating for its Medero Dark Grey variant, although the full range includes 12 colours, all produced from recycled pigments.

Beyond the certification, Kenoteq’s innovation lies in its low-energy process, which allows waste streams such as crushed brick, plasterboard, and mortar to be formed into a new masonry material without the need for high-temperature kiln firing. This approach not only reduces emissions but also diverts significant quantities of construction waste from landfill. The company’s co-founder and executive director, Sam Chapman, explains:

“Our aim was to create a technically robust, sustainable brick that performs to the same standards as traditional products. The K-BRIQ shows that circular materials can be commercially viable, scalable, and durable — not experimental.”

Kenoteq’s work has drawn recognition from across the construction and environmental sectors, winning awards from BE-ST, Zero Waste Scotland, and The Royal Academy of Engineering, among others. Early adopter projects already include Scotland’s National Retrofit Centre (BE-ST), Oaklands College in St Albans, and Kaufland’s sustainability-focused hypermarket in Germany.

As the construction industry intensifies its focus on embodied carbon and resource efficiency, Kenoteq’s approach demonstrates how regional waste recovery, precision engineering, and rigorous certification can combine to create viable building materials for a low-carbon future.

“We’re not just cutting emissions,” Chapman adds. “We’re closing the loop — transforming waste into a valuable, high-performance product that can be manufactured locally and used globally.”