Profile: Stone Automation

As discussed in our 30th Anniversary of Classico Marble article, the specialist stone fabrication and installation company spawned another key brand, Stone Automation, in 2022. To add even more layers to the onion, Stone Automation itself already represents five leading industry brands, some three years into trading.

The portfolio of Donatoni, Wodiam, Tesimag, Leica Geosystems and Slabsmith is extensive. However, with a little help from the managing director of both brands, Salvatore Caruso, the reasoning and advantages of those layers become all too clear - and serve as a reminder as to how and why they’ve continued to flourish as a business.

As Salvatore explains, it was hands-on experience in the Classico workshop that lit the touch paper: “the formation of Stone Automation was a natural opportunity because we were a loyal Donatoni customer, and we understood the fabricator market and the support it needed.” While working with Donatoni CNC bridge saws, the team recognised that another, separate piece of tooling was also playing a vital role in the precision cutting of stone for their expansive project portfolio: blades. The brand responsible here was Wodiam, and while expanding another earlier brand of his own, Salvatore recognised an opportunity to join the dots:

“We used Wodiam tooling at Classico Marble, and I had started to sell it through Italian Luxury Surfaces, another business I founded in 2015. Italian Luxury Surfaces was initially set up as a distribution business for natural stone sourced direct from Verona and Stone Italiana’s high-performance quartz, which my father had been using since the very early years of Classico Marble. This business gave us an insight into the fabricator market and a good understanding of the high-quality support and products they needed.” When Stone Automation was formed as the vehicle for the Donatoni distributorship, it was logical to move Wodiam away from Italian Luxury Surfaces and then keep tooling and machinery all under the Stone Automation umbrella.

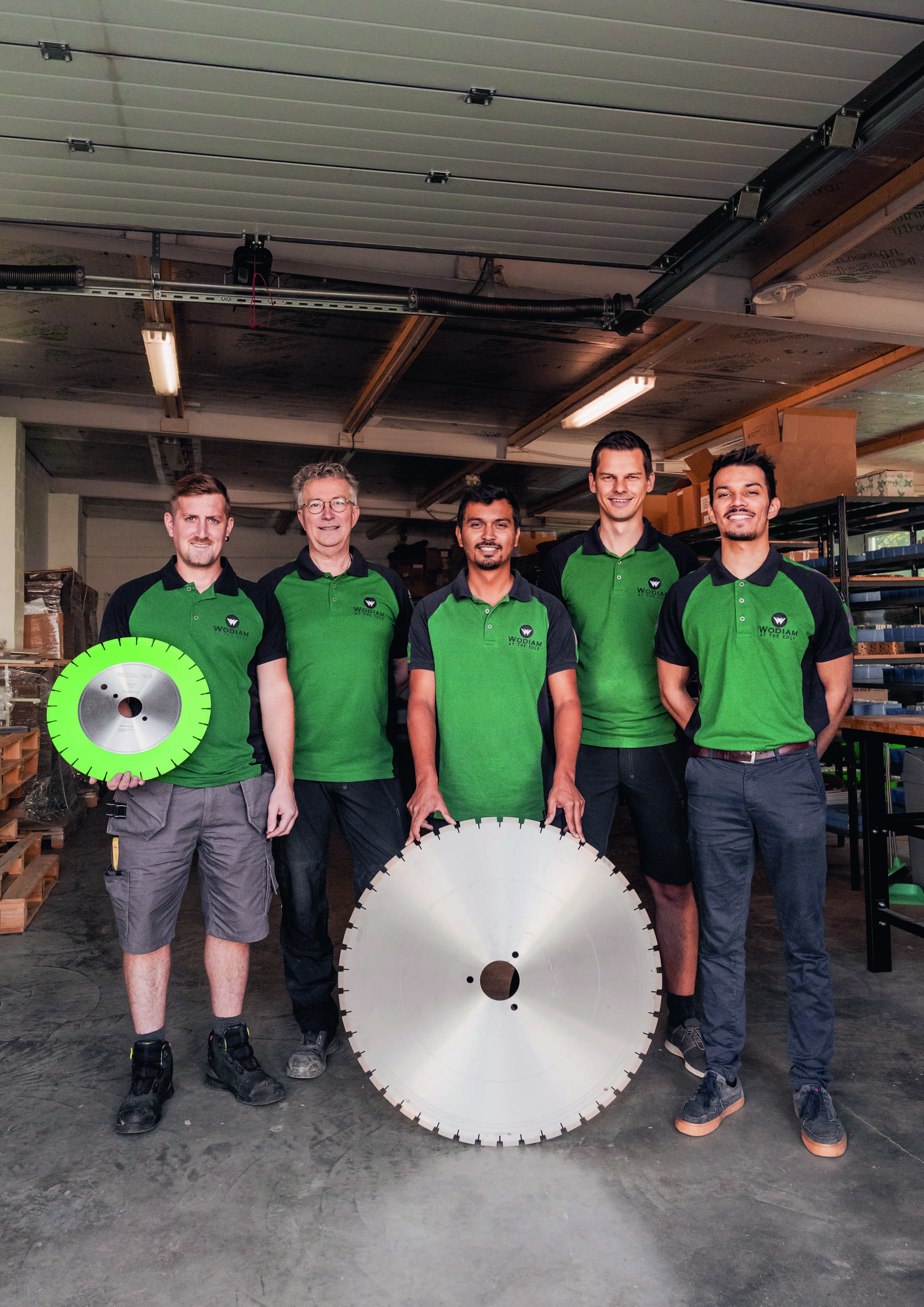

Like Classico Marble, Wodiam is a family business with a focus on helping stone fabricators improve the efficiency and quality of their work. Wodiam’s blades, routers and polishing tools are all made at their factory in Germany, and the technical support Wodiam offers fabricators is industry-leading. There is clearly a synergy, which Salvatore notes, “Their team and ours spend time with fabricators and operators at their machines, showing them how to use Wodiam tools and how to get the best speeds on their machines, no matter which material they are processing.”

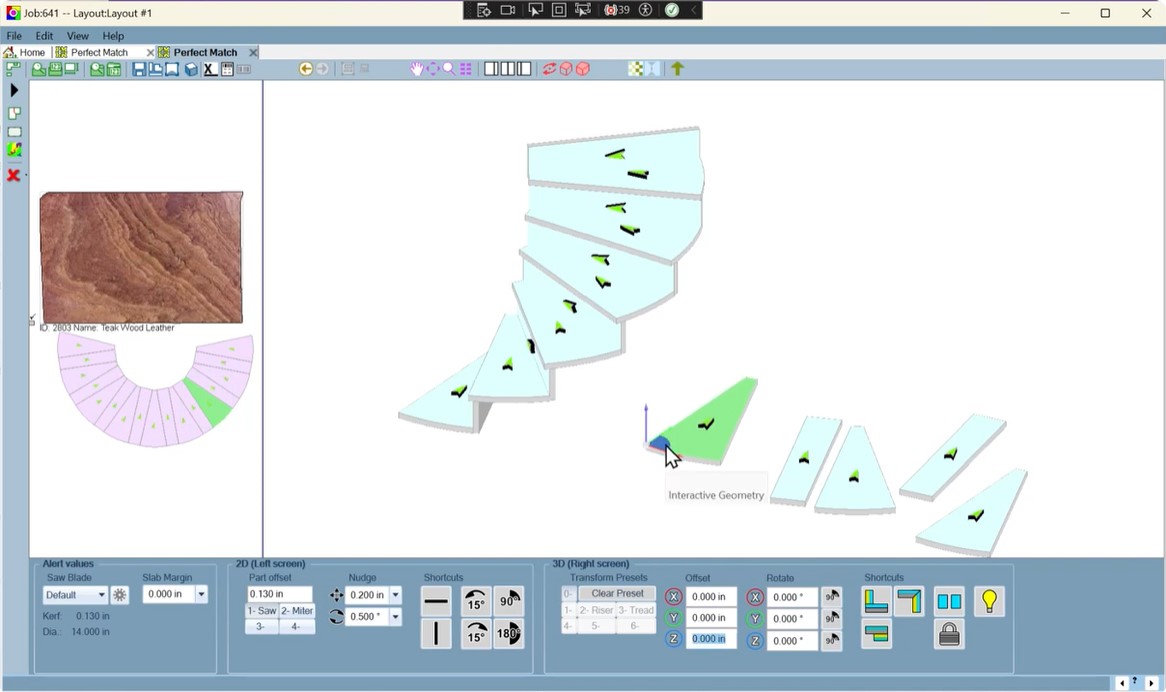

As a brand continually seeking new ways to enhance efficiency and client experience, it was a natural next step to start working with Slabsmith in the Classico Marble workshop. Slabsmith is a digital slab management software and system that can help a fabrication company streamline its inventory and overall slab management processes. With 10 years of experience with the product, it was only a matter of time before Stone Automation took on the brand, and Salvatore is keen to emphasise its value, “if you are a fabricator crafting book-matched surfaces for high-end projects, as a system, it is an absolute must.

Tesimag joined Stone Automation in 2024 just ahead of MarmoMac, and the company specialises in the design and construction of wastewater treatment plants, filter presses and advanced pumping systems with ranges created for the stone fabrication industry. As fabricators themselves, Stone Automation knows that stone processing businesses need better water filtering and treatment solutions to avoid costly downtime on the machines, and to reduce the cost of using precious mains water. Which, once again, makes Tesimag a natural addition to the portfolio.

Leica Geosystems is the latest brand to join the fold, and Stone Automation proudly distributes its robotic digital templating tools to the stone fabrication sector. Its introduction has added yet more positive layers for the company, as Salvatore describes, “Leica has also brought us into the marine, glass and canvas sectors for their templating tools, so we have recruited a new team to support those markets. Digital templating is 100% the future for stone fabrication, and with Leica’s tools, it is so fast, efficient and precise that it speeds up the whole templating process and helps avoid costly remakes.” As those in the industry know only too well, often it is the fabricator that foots the bill when it comes to remakes due to poor templating, but Salvatore thinks the Leica tool is the ideal solution as “it’s so precise, quick to set up and easy to use; every fabricator should consider it!”

With a rich history and a huge breadth of machinery, robots, and production lines stemming from their initial relationship with Donatoni, the five brands at Stone Automation enable them to cover most functions within a fabrication business, while offering high-quality support to fabricators post-sale.

So, whether it’s slab scanning and inventory management to water recycling and filtration, customers can expect honest and knowledgeable advice from a team that has used the products themselves, worked within fabrication businesses, and offers ongoing after-sales support once they have made a purchase.