by Stonegate Precision Tooling

It's important to pick the right blade for the material you are cutting to ensure your blade can match the strength of the stone. Choosing the wrong blade can lead to breaking the slabs or the blades, and the accelerated wear of the blade.

To ensure you always choose the right blade for the job it is important to understand the science behind the diamonds, the composition of the blade and what to look for when selecting the blade based on the material you intend to cut.

Let’s look at the blade

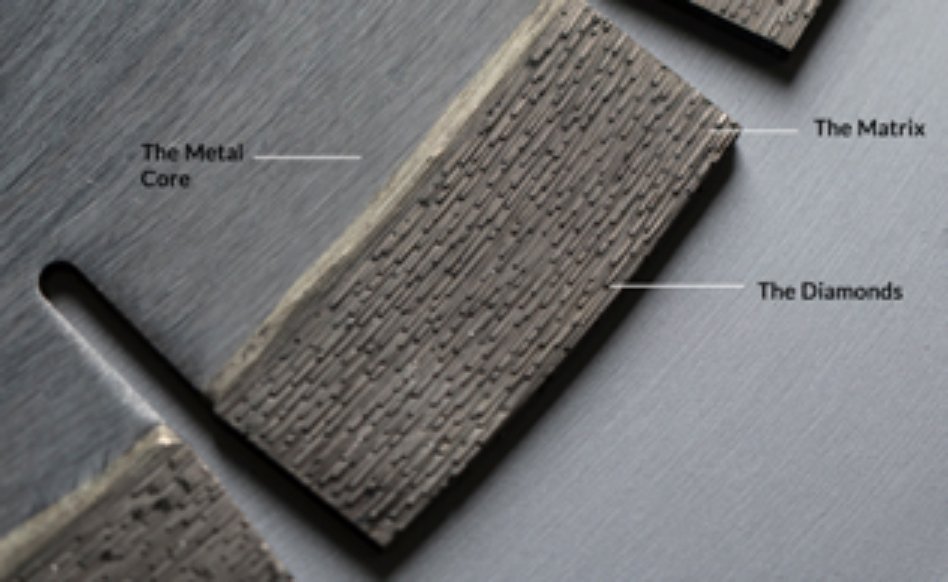

From the picture, you can see that the blade is made up of four different components. The Metal core is a steel disc that everything else is bonded to. The diamonds are the cutting teeth. The Matrix is the metal bond that holds the diamonds in place and the weld brings everything together to attach the matrix with the diamonds to the core.

The cut is essentially achieved thanks to the exposed diamonds on the edge of the blade slicing through the stone.

The wear and tear

The clever technology side of these blades lies in the wear and tear. When cutting through the stone the matrix will begin to wear away. This will loosen the old worn out diamonds and expose fresh new diamonds further down in the matrix.

This will allow you to continue to cut until the matrix is completely worn away. To ensure you are getting the best out of your blade you should stock up on diamond sharpening blocks in your tool kit. These will help you to keep your blade sharp by helping to expose fresh diamonds so you are always getting the best cut.

Choosing the right blade for the job

Choosing the right blade for the job means getting the right hardness of the matrix bond for the hardness of the stone.

A softer material (such as engineered quartz) will not wear out the diamond cutting edge as quickly as a harder stone. This means cutting quartz requires a blade with a harder matrix bond to ensure the diamonds are used to their full potential before they are lost.

Harder stones and some of the latest man made materials, such as Dekton, will wear the diamonds much faster. This means they a softer matrix bond is needed to enable a faster erosion of the matrix.

A harder bond would keep the used diamonds in place for longer, which would give you a blunter blade and less clean cut.

A blade with a softer bond, such as the Evogres from Stegate, will keep up with your diamond requirements and expose fresh diamonds faster, ensuring optimum cutting performance.

Stonegate does recommend that when you cut Dekton you always use the sharpening block on your blade between jobs to ensure you are cutting this tricky material with fresh diamonds.

Part of the testing process at Stonegate is to ensure the best bond is available for the material you are cutting, while also focusing on new technology to develop better blades that will last longer, like the Stonegate signature Tempest blade.

The Tempest is exclusive to Stonegate. It uses arranged diamond technology which gives you a better cut and lasts as much as three times longer than previously available blades.

And you cut not only faster but also at a consistently high standard.

The Tempest blade was the first blade of its kind to take the industry from the standard 15mm segments to 26mm segments and it has quickly become a fabricator’s favourite.

A year later, Stonegate launched the Conqueror blade.

This was not intended to match or supersede the speed and longevity of the Tempest but was designed as a solution to another problem – that of mitring or radius cutting on a CNC saw.

Mitring and radiuses cause stress on the blade, which can bend or sometimes break it. The conqueror has a thicker, stronger body, with location peg holes drilled at the point of manufacture.

Drilling the holes after manufacture can sometimes release some of the tension in the blade. Drilling during the processes before the tension mean the blade is stronger to cope with the stress mitring or cutting curves.

Stonegate and Cosentino – partners in Innovation

Stonegate Precision Tooling and Cosentino have been partnered for almost six years to provide fabricators with the tooling to cut innovative new materials.

Stonegate works hard with manufacturers to create tooling that will give the best possible cut for the ultra-compact surfaces of Dekton.

The tooling is sent to Cosentino for approval. When Cosentino accredits tooling, its means that Cosentino trusts it and offers to replace a slab if it cracks.

The range of Stonegate tools accredited by Cosentino include:

- Evogres DEKTON Blade

- Z45 tooling

- Core Drills

- Blind core drills

- Segmented stubbing wheels

- Routers

- 125mm Segmented blades

- Seam-It adhesive

These tools are stocked by Cosentino itself in its depots around the world and are used by the company’s own factories every day.

The innovation has not stopped. New developments are currently being tested ready for release in the next few months.

Some fabricators are still struggling with Dekton and below Stonegate offers some useful tips to get the best from its Dekton tooling.

Stonegate’s Top Tips:

- Always sharpen your blade or core drill with the blue sharpening block before use. This exposes new diamonds.

- Cut Dekton at the feed-rate and speeds recommended by your tooling supplier. For Stonegate’s recommendations visit www.stonegatetooling.com, or call one of the company’s technical team representatives, who will be happy to talk you through the guidelines.

- Use twice as much water as you would for any other material

- Before shaping your slab, cut 15mm off the edges to relieve the tension, starting with the long edge and finishing with the short edge.

- Slow the speed of the tool to one-third of that recommended as you enter and exit the stone

- When mitring, use as small a blade as possible.

For more tips about how to get the best from your tooling, or for advice on the right tool for your job, get in touch with the Stonegate Technical Team.

Getting the best out of your CNC routers

Technology is moving fast, helping fabricators expand their businesses and get more jobs out the door.

Routing out a sink cut out can be a slow process that causes a bottleneck in the workshop. The Status High-Speed Router from Stonegate has been manufactured with smaller, angled segments. It is lighter than its counterparts in the Status range but that does not sacrifice performance.

This High-Speed Router is capable of running at nearly twice the speed of the standard Status tools. It is manufactured with arranged diamond technology for the best possible cut.

It can achieve speeds of 350-400mm/min on granite and 400-700mm/min on engineered stone.

The Status high-speed router has a reinforced end segment for plunging and rebating and a medium/hard bond for a long life while still being able to cut almost any material with exceptional speed.

New last month (September) was the Status four segment router. It has the same arranged diamond technology as the seven-segment high-speed router, but pushed to its max can reach speeds of 750mm/min on quartz and 350mm/min on granite.

For companies making 30-50 worktops a day, productivity is important, but when the speed is increased the life of a tool can suffer. The solution to increasing the longevity of your router is on tap – it is water.

More water will ensure your router does not get too hot and burn away not only the tool but in some cases the stone itself.

When pushing your router to the limit the volume of water volume going through your tools should be 19/20 litres a minute.

This will not only ensure the router and stone stay cool, but also that the tool does not wear away too quickly. If you cannot get that much water to the router you might have to slow your speed down.