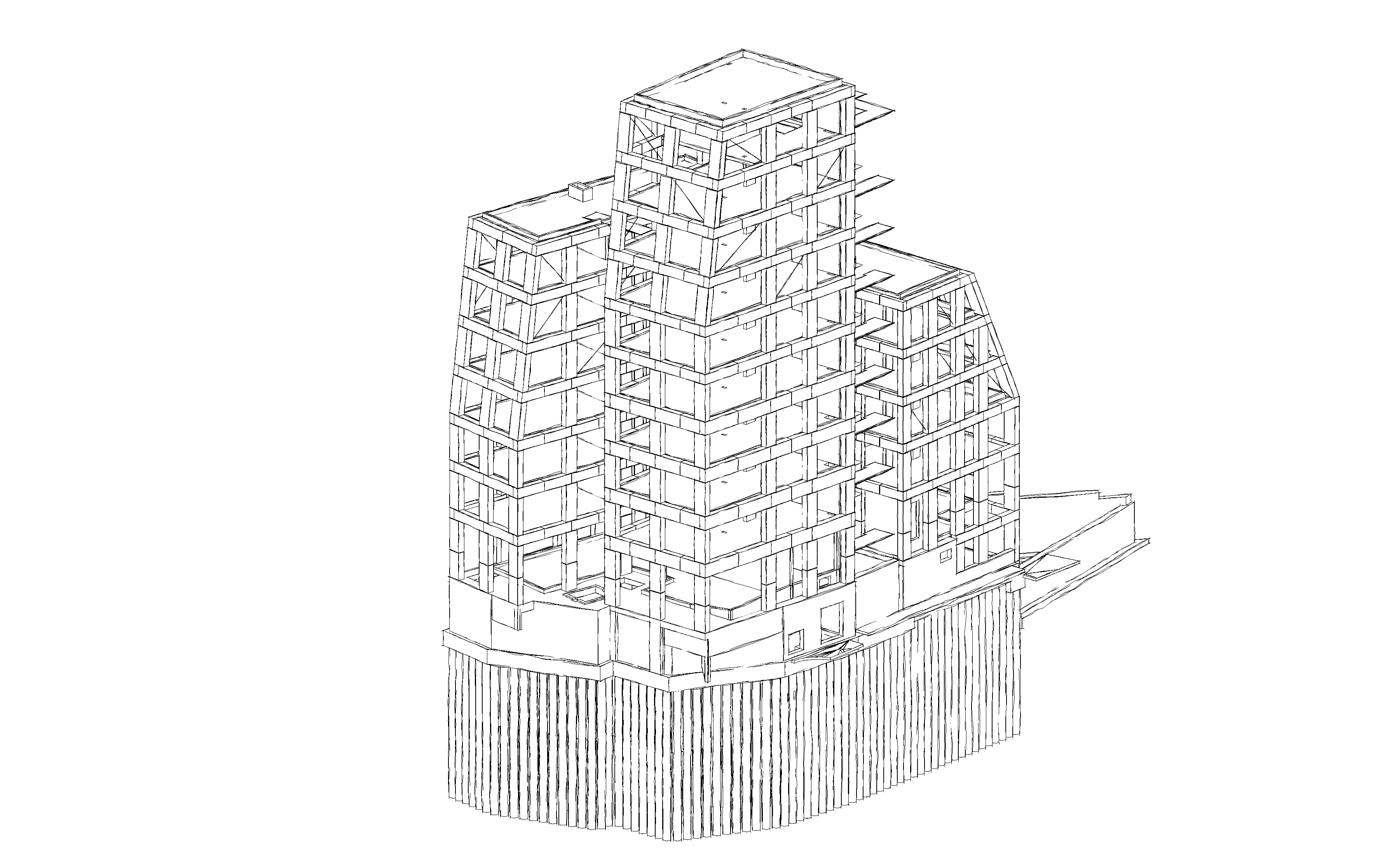

Case Study: WIP at Finchley Road

The redevelopment at Finchley Road continues to evolve as one of the UK’s most ambitious demonstrations of load-bearing stone construction. Although still a work in progress, the project has already become a reference point for architects and engineers exploring alternatives to carbon-heavy steel and concrete. The scheme, designed by Groupwork and led by architect Amin Taha with structural engineering from Webb Yates, has followed a winding procurement journey with plenty of changes along the way. Yet its central idea has remained: a tall, fully structural stone exoskeleton built to modern fire standards, offering long-term carbon savings through minimal processing and an (almost) self-finished envelope.

Image Credit: Webb Yates

The stone frame has been designed as a sway frame, with fixed connections between beams and columns. Webb Yates built a full-scale connection mock-up to test the connection strength, which was tested under 1.5 times the design loads. Elenaora Rigni of Webb Yates explains the basic principles:

“To minimise tension and bending moments in the beam elements, the frame was designed so that all vertical loads are carried by the columns, allowing the beams to act primarily in tension to provide lateral stability.”

At its highest point, the building is set to be 10 storeys high, which called for a dense igneous stone for the exoskeleton structure, with Italian Basalt originally chosen for its compressive strength and compliance with new fire regulations. Yet, as practical as such stone may be, it has its limitations, which, along with the site’s many restrictions, have led the team to some creative problem-solving.

Located close to Finchley and Frognal station, the space is somewhat tight, and as Elenora underlines, “Due to Network Rail safety procedures, the crane was subject to strict lifting limits, so the stone elements were designed to fall within those limits.” What’s more, being a natural material does have its drawbacks, not least in terms of the sizes available. In requiring very long lengths of stone, the team were faced with a challenge. Drawing on their collective experience of producing Clerkenwell Close, the team has once again used a splicing method, which Amin describes as “stitching stones together to allow longer column and beam spans, opening the structural grid.” As Elenora adds, this also allows “heavier elements to be divided into smaller sections that can be assembled on site.”

Of course, all builds involve a network of companies, specialists and suppliers, and with Finchley Road, there have been moments of unpredictability, as Amin illustrates, “The project has been bought and sold three times, which also meant a change of main and subcontractors.” Having originally begun the build with AteliersRomeo’s Sicilian basalt, the most recent evolution has seen the introduction of Lundhs’ Norwegian larvikite. As Elenora points out, the material “offers a compressive strength of around 170 MPa, compared with approximately 35–40 MPa for standard concrete.” Amin also notes that the general use of stone produces “ 98% lower CO2/m3 than reinforced concrete or fired clay brick and 99.6% lower than mild steel.”

The larvikite was manufactured within Lundhs quarry facilities near the southern coast of Norway, and from there, they were shipped to Tilbury and Immingham docks for onward transport to site. Lundhs’ business development manager, Ben Ayling, knows all to well how complicated it has been to get the material onto site, and stresses that cross-party collaboration was key:

“As storage space on site was very limited, deliveries had to be carefully sequenced and timed to support continuous installation. Loading operations also relied on the temporary use of an adjacent bus lane, which made precision and coordination essential. Through close communication between the construction company, Ernest Park, and our project manager, we maintained an accurate delivery rhythm that minimised storage risks and supported a smooth, uninterrupted build programme.”

The programme has steadily begun to run more smoothly, with a notable structure rising up, and already grabbing the attention in a busily built-up area. Internally, the larvikite has shown its versatility, with single pieces used to form the floor-to-floor lift core, while standard brick laying techniques have been used to produce the service riser from larvikite blocks. Amin states another benefit here, “Being self-finished stone and needing neither fireproofing layers nor extra finishing layers saves a considerable amount of costs and carbon.”

Although the eagle-eyed amongst you may note that the exterior aesthetic of this emerging structure has been altered from its original state. Indeed, the dark tone of the larvikite has been veiled by a coating of dusty red paint. Ben explains that, “The requirement to paint the stone came from local planning rules intended to reflect the area’s Victorian red brick character.” In many ways, this could be viewed as a compromise on the material, but Ben adds, “it’s a small price to pay to realise a load-bearing stone project of this scale.” For Amin, overcoming the initial discomfort of this procedure may also have led to a happy accident:

“At first we were reluctant to the idea, but when told by a British quarry that this method had been used for generations to match stones fresh out of the quarry to those standing for hundreds of years, we realised it was a new line to investigate for this and the next projects.”

It has also allowed the team to create moments of contrast within the building's overall design, with those self-finished internal elements remaining in their natural state - and soon to be unveiled, as this bastion of structural stone draws close to completion.