More likely the influencing factor is the diminishing gap between the price of indigenous and European stone and the price of stone from the Far East.

A local stone has the essential character of the area where it is to be used, which is an appealing feature for some projects, and there is a comfort factor in using a stone with a provenance that shows it can survive the vagaries of the British climate, especially as some of those who have imported stone without any knowledge of the materials they are dealing with have discovered to their (and their client’s) dismay that stone is not all the same.

It seems to have proved difficult for some specifiers and clients to understand that stone is not a commodity that they buy simply on the basis of the lowest price. But they are learning. As natural granite and sandstone, in particular, have become the materials of choice in many hard landscaping projects, so those choosing them are learning from experience that they will not all perform in the same way.

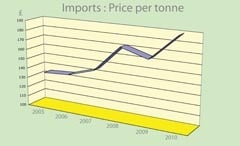

Of course, when money is tight (and even when it isn’t), price is an influencing factor, but as the graphs on the right show, the price of stone imports for hard landscaping has been rising quite sharply – up 40% since 2005.

The government figures only provide a snapshot of stone imports for hard landscaping. They do not include all the stone hard landscaping imported because of the way materials and products are classified, but they do indicate trends. There are no reliable figures for dimensional stone production in the UK, but anecdotal evidence from the British quarries that produce hard landscaping suggest demand has held up reasonably well and, as the import figures also show, saw some improvement last year.

However, according to the producers, the market has resisted price increases of British stone. In fact, the price of some products has fallen back to the levels of 2005, while the exchange rate and a big increase in the price of shipping last year contributed to the continuing upward trend in the price of imports, 90% of which by value and 94% by volume come from the Far East.

By far the majority of stone used in hard landscaping, for both commercial and domestic projects, is imported and the lower price of imports has played a significant part in the growth in popularity of the natural material. But if imports have done the groundwork in educating customers about stone, it looks as if British producers are starting to benefit from a more discerning clientele.

Portland limestone paving chosen for Olympic sailing centre

Portland Marina, redeveloped from the old naval base on the Dorset island, is to be host to the 10 sailing events during next year’s Olympic Games.

The development of the marina includes an impressive display of the island’s famous Portland limestone, both as paving outside and as floors on the interiors.

Limestone is not always ideal as paving because it can polish and become slippery, especially when wet, but the shelly Grove Whitbed from Albion with its 50grit finish surpasses slip resistance standards for paving by a significant margin. Inside it is honed to 120grit. It was also used for a post marker carrying the name of Portland Marina (pictured right, at the bottom).

Other stones from Albion were also used in the project. A memorial to sailors who drowned on their return journey to the aircraft carrier HMS Illustrious in World War II (pictured at the top) is made from the cleanest of Albion’s stones, Jordans Basebed, while the bench (in the middle) is from Roach, the liveliest of the Portland beds.

www.albionstone.com

Ultrascape launch PaveJoint

Instarmac Group have launched PaveJoint under their Ultrascape brand. It is a simple brush-and-add-water jointing solution for drives, paths and patios.

Launched at the World of Paving & Hard Landscaping Show at the RICOH Arena, Coventry, in March with daily demonstrations, PaveJoint is a ready-to-use jointing compound suitable for block paving, setts, cobbles and flags. It is simply swept into joints before adding water.

Available in both buff and natural grey, it is clean to use and there is no waste because it is not air-curing, so unused product can simply be re-sealed in the tub for future use. It can fill joints from 2mm to 25mm and it will prohibit the growth of weeds and moss. It is even environmentally friendly because it contains recycled materials and enables paving to be re-used in the future.

www.ultrascape.co.uk

Marshalls pave Whitehall

As one of the most famous streets in London it was imperative that when Whitehall, at the heart of Westminster and the seat of government, was paved it should reflected the status of the area as well as complementing the aesthetics of its classical architecture.

Whitehall had a combination of concrete slab dating back to 1905 and tarmac, added much later. Whitehall wanted better and what they chose was Moselden Yorkstone Paving from Marshalls’ Natural Stone range.

This was the first major installation of the stone paving from a new quarry opened by Marshalls in West Yorkshire – and coming from the UK it offered sustainable sourcing.

More than 10,000m2 of diamond sawn buff and silver Moselden Yorkstone Paving was used in this project. The majority of the paving is 600mm wide x 63mm thick in random lengths, which looks good, emphasising the fact that it is a natural material, and reduces the waste in the production of the paving. There are also 50m2 of blister tactile paving for crossings and 15m2 of 100 x 100mm paving setts, 75mm thick, as a feature.

www.marshalls.co.uk

So green Forest Pennant

Forest of Dean Stone Firms, who quarry and process Forest Pennant sandstone from the Forest of Dean, Gloucestershire, supplied more than 1,800m2 of their Royal Forest Pennant sandstone paving for the pedestrianised zones along Duke Street in Cardiff. The paving is in a conservation area and was partially funded by a Welsh Assembly Government Transport Grant, part of the first ever National Transport Plan for Wales.

Having specified Forest Pennant on a number of previous occasions, main contractors Birse Civils, working on behalf of Cardiff City Council, had no concerns about the supply of the hard wearing and high quality product for the paved surfaces. And it enabled them to meet the stringent sustainability and carbon footprint criteria of the council’s specification because the Forest Pennant sandstone is the most environmentally friendly stone in the UK, with almost zero carbon processing thanks to the company’s hydro electricity generating plant (featured in the previous issue of NSS).

Forest Pennant paving was also used for Hereford City Centre’s Refurbishment scheme, which opened in time for the festivities just before Christmas. There, 1,500m2 of it helped complete the street enhancement scheme.

The local Pennant sandstone was selected as a naturally complementary material to the existing historic city centre buildings.

www.forestpennant.com