As promised, we are taking a deep dive into the Stone Demonstrator - one of the most seminal stone-related projects to emerge in recent times. Here, we talk to some of the key players involved in the project to discover how collaboration and proactivity have made a case for structural stone.

The Stone Demonstrator is not a pavilion, a folly or a symbolic gesture. It is a working structure, conceived as a full-scale research tool to test whether load-bearing stone can operate as a credible, low-carbon alternative to steel and reinforced concrete. Commissioned by the Design Museum’s Future Observatory and installed on the Earls Court site in London, the three-storey prototype brings together nearly 20 partners across architecture, engineering, quarrying, stone supply, masonry and academia. Its purpose is straightforward: to show, in built form, that structural stone is not only possible, but practical.

Future Observatory, the Design Museum’s national research programme for the green transition, initiated the project as part of its work on low-carbon housing. As Justin McGuirk, Director of Future Observatory, explains, the ambition was to move beyond theory. “Future Observatory is committed to supporting research into low-carbon construction methods, and the Stone Demonstrator is an ambitious contribution to the field,” he says. “It’s a building as a research tool, a 1:1 scale demonstrator of an ultra-low-carbon structure for the sector to study.”

From the outset, the project was structured around collaboration. Groupwork was appointed as architect, with structural engineering led by Webb Yates, working in collaboration with Arup. The Stonemasonry Company developed and delivered the structural stone system, while Earls Court Development Company (ECDC) provided the site. Quarries, stone suppliers and brick manufacturers were engaged early to ensure that the material reality matched the research ambition. “There were nearly twenty partners in this project,” McGuirk notes. “Architects, engineers, stonemasons, quarries, timber companies, contractors etc. So collaboration was absolutely key.”

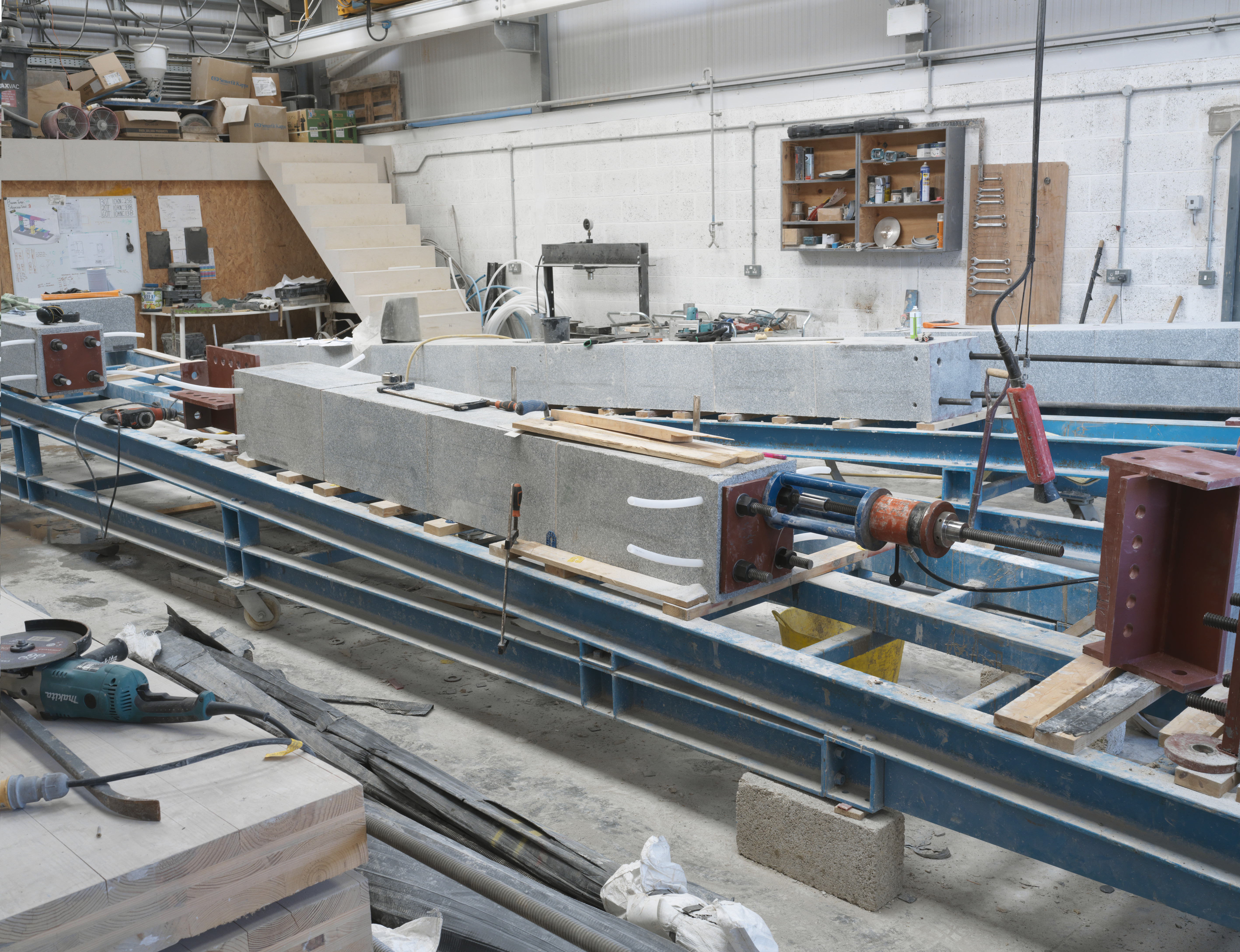

At the heart of the Demonstrator is a pre-tensioned stone frame developed and patented by The Stonemasonry Company. The system uses mechanically connected stone elements – beams and columns – assembled with threaded steel bars that are tensioned to place the stone into compression.

“For the last 15 years, the stone masonry company had been pioneering a way to allow for stone to be used as a structure in place of concrete,” says Pierre Bidaud of The Stonemasonry Company. “Through our studies, we have found a distinct system that uses mechanical connections, which means all our beams and columns can mesh very efficiently and with other materials.”

A key objective was to remove the perception that stone construction requires specialist, time-intensive skills. “If you know how to use a spanner, the system can be easily deployed without any special or lengthy training,” Bidaud explains. “The people who built the Stone Demonstrator structure were not stone masons; they were people who ordinarily construct steel or concrete frames.”

Much of the work happens off-site, “because we want a fast deployment, there needs to be a clear cutting sheet and for the stone to be drilled, before the rebar is fitted through the holes,” Bidaud says. “The rebar is then tensioned, which means compression is transferred to the stone, and that’s it.” Following around nine days of workshop preparation, the stone frame was erected on site in approximately six days. “We have patented a very simple process,” Bidaud adds, “and it allows us to put a low-carbon structure in place quickly.”

Material choice was also deliberate. “We have used predominantly granite and limestone, as well as the stone bricks,” he says. “But importantly, it’s been made with discarded material, or material that is deemed to be unusable by the quarry – essentially it’s using all the wonky vegetables.”

While the system is visually legible, its credibility rests on engineering rigour. Webb Yates’ involvement spans nearly two decades of research into structural stone, and the Demonstrator consolidates that work into a single, accessible structure. “It’s intended to demonstrate a viable alternative to everyday building methods ,but at a fraction of the embodied carbon, this structure brings together almost two decades of prototyping and testing,” says Amin Taha, Founder and Chairman of Groupwork. “Its purpose is not to promote stone for sentimental reasons but as an ultra-low-carbon alternative.”

Steve Webb, Board Director of Webb Yates, places the argument in a wider context. “The stone in this frame is produced with a fraction of the energy required to produce the alternative materials,” he says. “Adopting stone as a staple building material would close coal mines and not require their replacement with green alternatives.”

For engineers, the challenge is not only material performance but confidence. “There are definitely challenges to starting with structural stone, but also a lot of interest and ambition across the profession,” says Liam Bryant of Webb Yates. “It isn’t really about the material itself, but the attitude we bring to it.” Bryant acknowledges that the absence of dedicated design codes is often cited as a barrier. “While this is an area for improvement, and there are multiple efforts ongoing, it isn’t a complete block,” he explains. “BS EN 1996 does give some methods that can be adapted for working with stone.” He does however stress that testing is critical: “Physical testing not only gives engineers the data we need, but also helps contractors and clients become more familiar with the material,” adding, “There’s a lot of progress and development in the field, and I’m confident there are plenty of engineers ready to take up the challenge.”

But the figures tell a very planet-positive story. Stone Demonstrator achieves substantial carbon savings: around 90% compared to a steel frame and 75% compared to reinforced concrete. Although only three storeys high, its implications extend much further. “We only built a three-storey prototyp,e but the engineers tell me this system could be used for a 50-storey building,” McGuirk says. Regulatory thresholds remain a consideration. “Anything over 18m high changes the fire regulations, so that is currently the limit,” Bidaud notes. “But a 20x20m, 6-storey building only takes around 100m³ of stone – it’s quite a small sampling from a quarry.”

Future Observatory has already funded the next step. Professor Wendel Sebastian at UCL is developing a design guide informed by sensors embedded in the structure and laboratory testing. “The accompanying design guide being produced by UCL is another key step in the adoption of structural stone,” McGuirk says. The ambition is market transformation. “The idea is that the prototype helps drive adoption and further experimentation,” he adds, “encouraging demand for load-bearing stone, creating a market that begins to provide viable alternatives to steel and concrete – used in conjunction with timber.”

While the design of the structure is fundamental, collaboration has been essential, with a number of stone suppliers playing an important role. Marcus Paine of Hutton Stone explains: “We were directly involved in supplying the UK Stone Bricks for the exterior walls… We donated our Darney Heritage Sandstone Bricks and Albion supplied their Heritage Portland Stone Bricks, which the team then decided to blend on site. For Paine, the Demonstrator is about industry-wide change. “This is not simply about individual companies promoting their products,” he says. “It really is entirely focused on a viable and sustainable route forward for the entire Natural Stone Industry in a lower-carbon built future.” Michael Poultney of Albion Stone agrees. “The stones are off the drawing board and sat on site where nobody can ignore them,” he says. “Visually demonstrating that stone is capable of performing structurally in the real world.”

The location matters. “At the Earls Court Development Company, sustainability is a cornerstone of our vision,” says Peter Runacres, Head of Urban Futures. “We’re proud to host the Stone Demonstrator – a striking prototype that embodies our commitment to sustainable urban development.” As Professor Christopher Smith of UKRI AHRC concludes: “Through the Future Observatory… we are quite literally building the future.”

The Stone Demonstrator does not claim to be the only solution, but it makes a compelling case: that through collaboration, testing and openness, structural stone can move from the margins to the mainstream.