William Tribe Lamb founded W T Lamb & Sons as heavy side builders merchants, with his two sons, Bertrand and Antony Ernest, in 1901. They then purchased their first brickworks in 1910. The company was subsequently run by Antony and Richard Lamb, sons of Bertrand, prior to currently being run by the fourth and fifth generations. It is believed that W T Lamb & Sons Ltd is the oldest brick making company in the UK still owned by the founding family. The company supplied and manufactured bricks for the Victorian buildings of London and the South East with fine handmade bricks, thrown and clamp-fired in Essex, Kent, Surrey and Sussex.

Five generations later, Lambs is still a family-owned business with a focus on providing quality products to the building industry. The fourth generation Group Chairman, Robin Lamb, who joined the company in 1959, worked his way through accounts, roofing and sales departments, before becoming Sales Director, then Managing Director, before assuming his current position. Robin's son James is also on the Board and has been an active non-executive director since 2000.

In 2001, Jonathan Lamb became Sales Director, with his father, Robert, taking over the role as Managing Director.

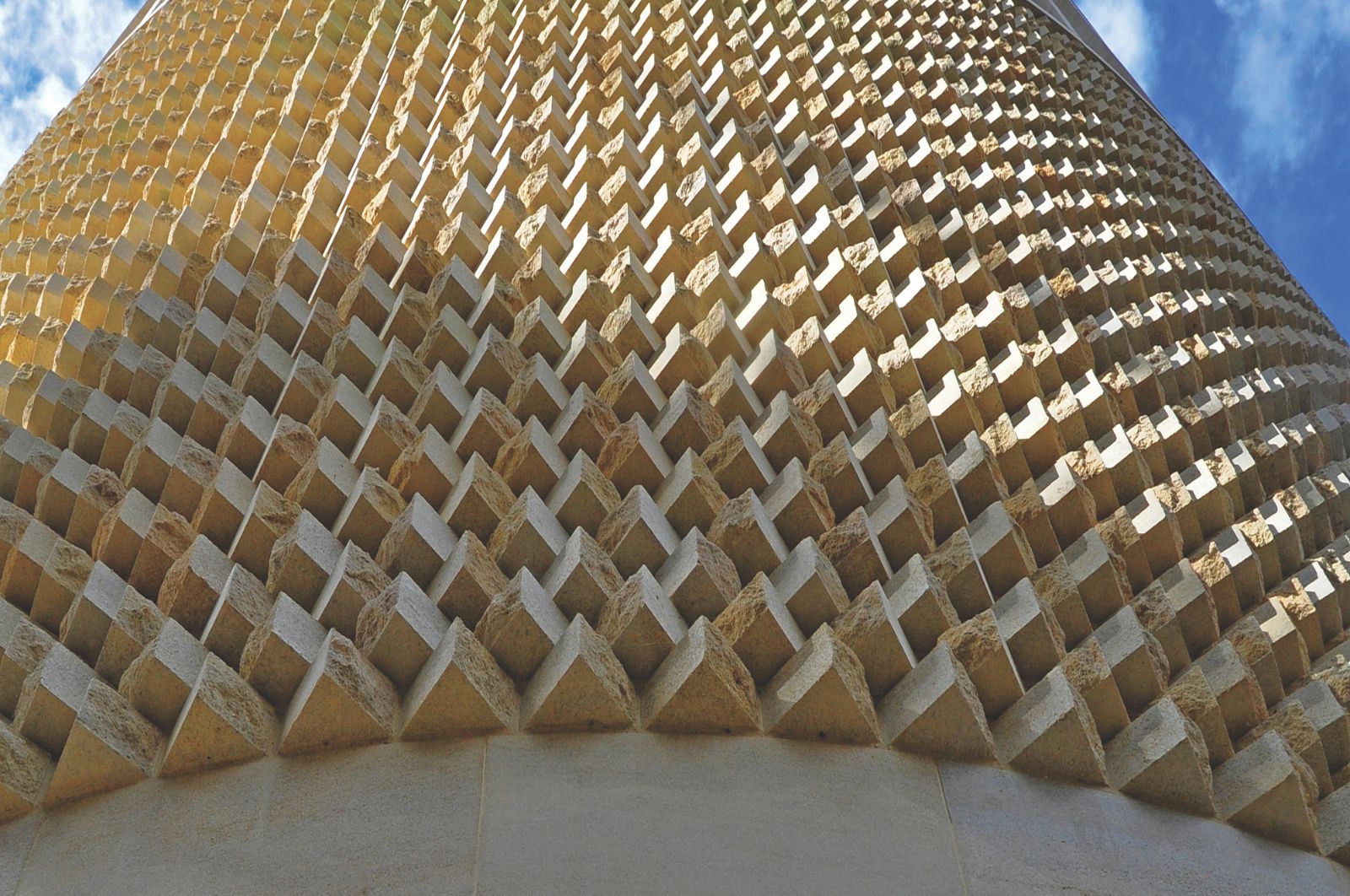

During this period, the brick industry continued to evolve and Lambs’ success continued, supplying some of the most iconic buildings in the UK.

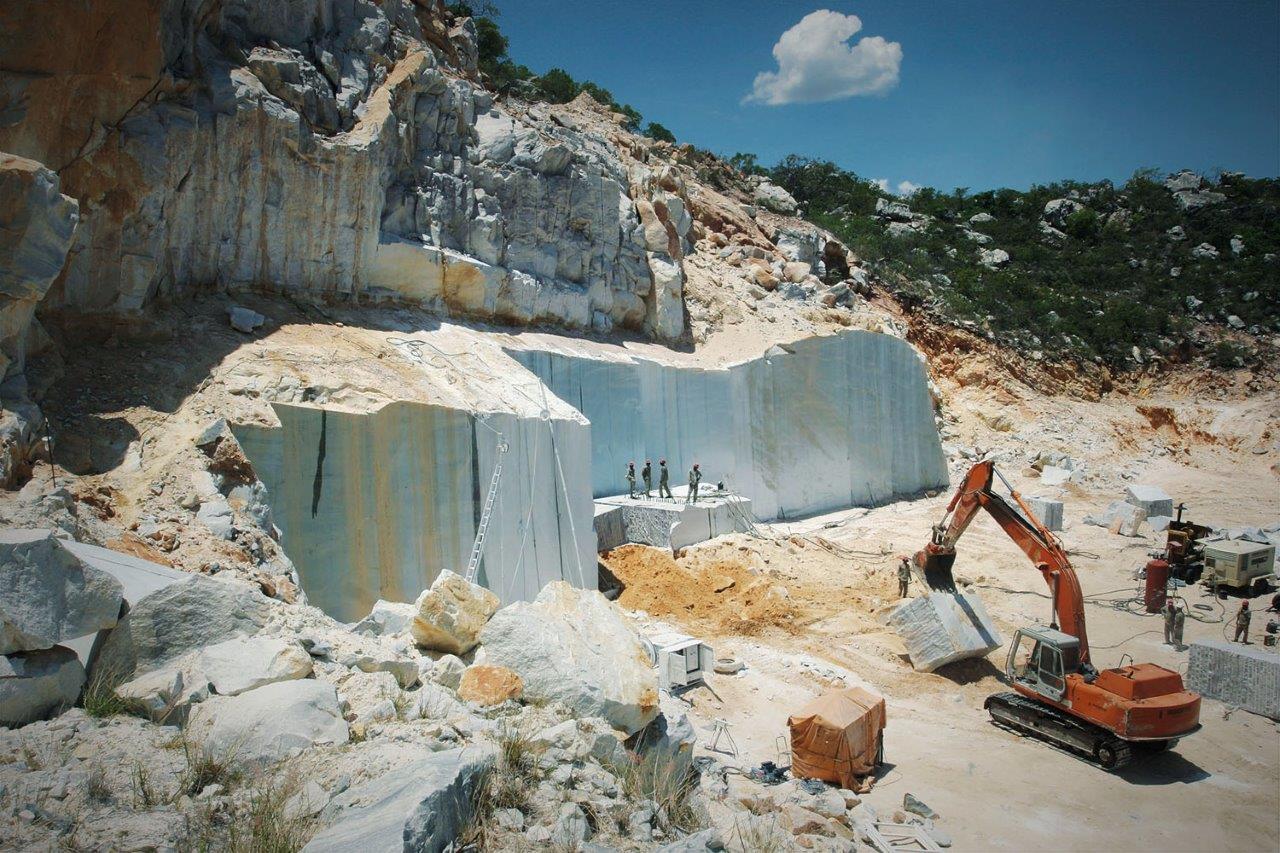

Building on our reputation for quality and for providing authentic British building materials, Lambs expanded from bricks into natural stone.

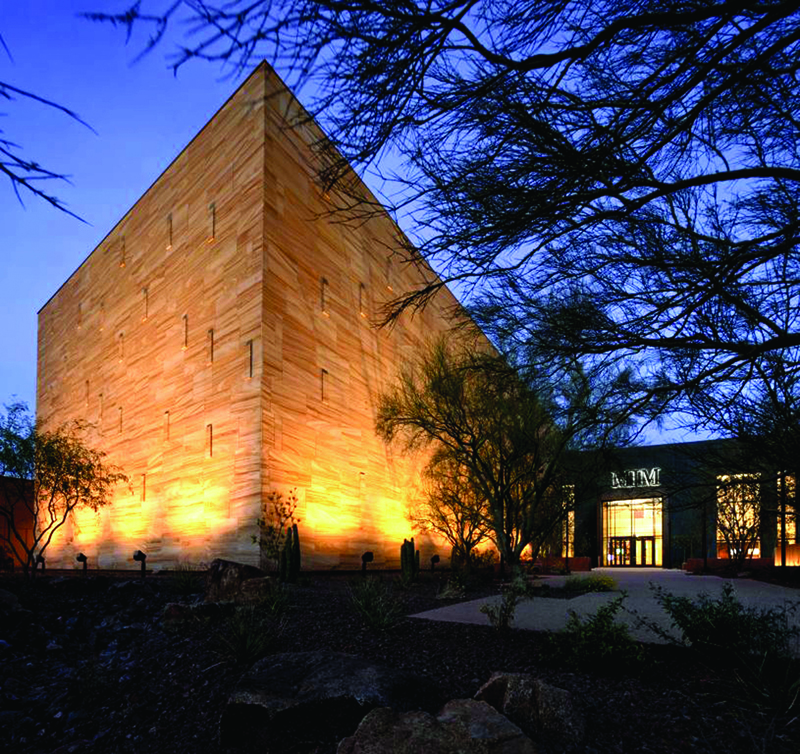

In 2004, Lambs secured the right to excavate, and later purchased, Philpots Quarry, the last remaining large source of Wealden Sussex Sandstone in the UK.

Lambs continue to produce hand made specialist bricks and rubbers to some of the finest buildings to this day, whilst challenging our experienced staff with complicated brick detailing.

The leading supplier of sustainable, ethically quarried natural stone, offering expert architectural services.

As the owner and operator of Clipsham Medwells and Clipsham Bidwells quarries on the famous Lincolnshire Oolitic belt, Stamford Stone Company is the exclusive global supplier of Clipsham limestone.

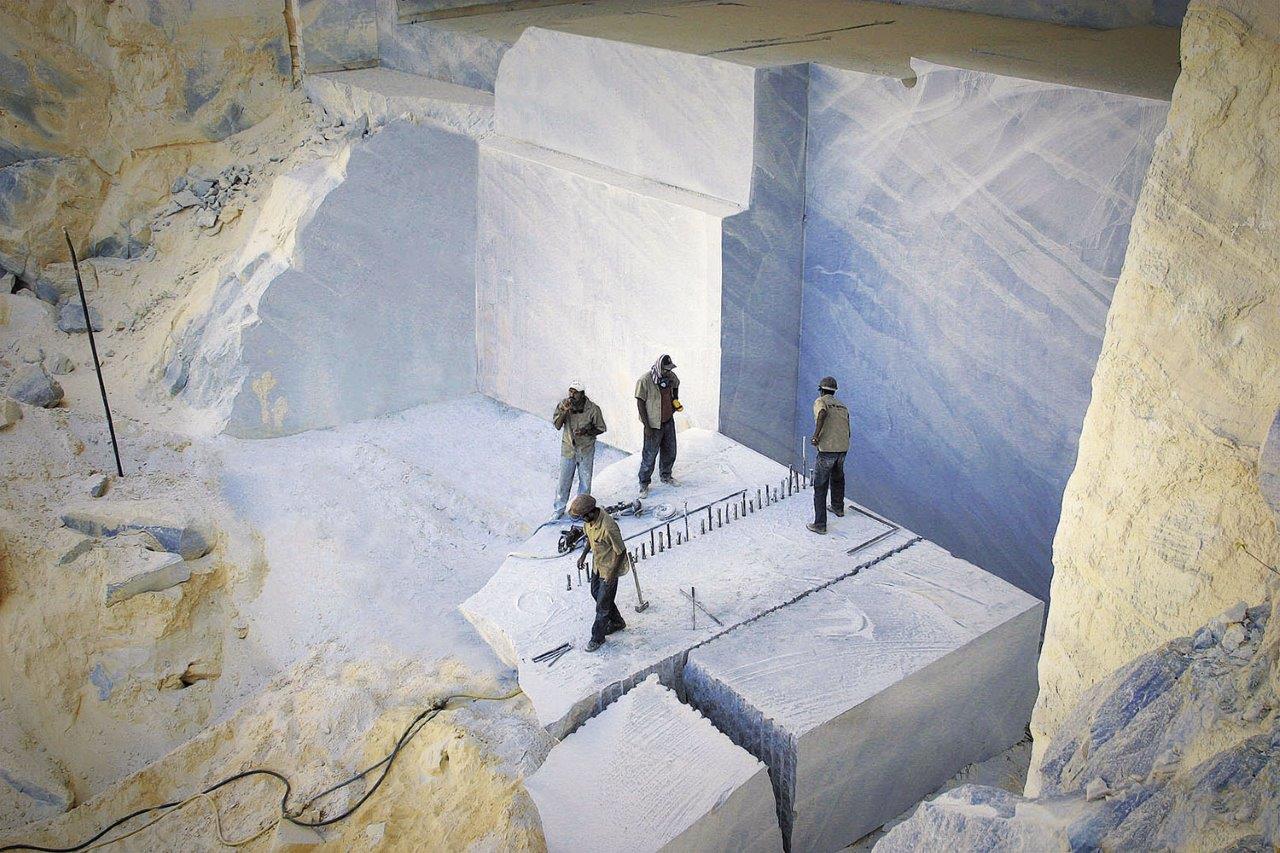

Owning their quarries allows Stamford Stone to prioritise a sustainable and ethical approach at every stage of the stone production process. These eco-friendly practices even extend to harvesting and recycling rainwater, repurposing by-products into useful resources, and developing full replanting and re-landscaping plans. This dedication to sustainability guarantees reserves of this appealing and historic stone for the next 900 years.

As well as sustainability, Stamford Stone is committed to expert craftsmanship, combining cutting-edge manufacturing processes with traditional methods to ensure high-quality products backed by heritage. Their purpose-built processing site includes an efficient CNC machine and a fully automated Donatoni tile line to ensure quality and consistency when transforming raw materials into architectural products for domestic and commercial building projects.

Exceptional architectural services for award-winning conservation, restoration, domestic and commercial projects

Stamford Stone’s status as experts in architectural stone allows them to offer comprehensive support for building projects of all kinds. Their architectural services include using advanced 3D Point Cloud software to scan existing buildings for restoration, and creating detailed 3D concept drawings for new builds and extensions. They also provide a stone fixing service informed by the specialist knowledge of their on-site team.

All this expertise makes Stamford Stone the supplier of choice for housebuilders wanting to blend new developments into existing environments, and conservation specialists looking to carry out repairs that blend seamlessly with existing architecture. Clipsham limestone is also a popular choice among architects for award-winning projects in historic cities like Oxford and Cambridge.

Architectural excellence with natural stone

Stamford Stone are natural stone experts with the comprehensive architectural knowledge to offer design guidance, project management, stone fixing and a full CAD drawing service all under one roof.

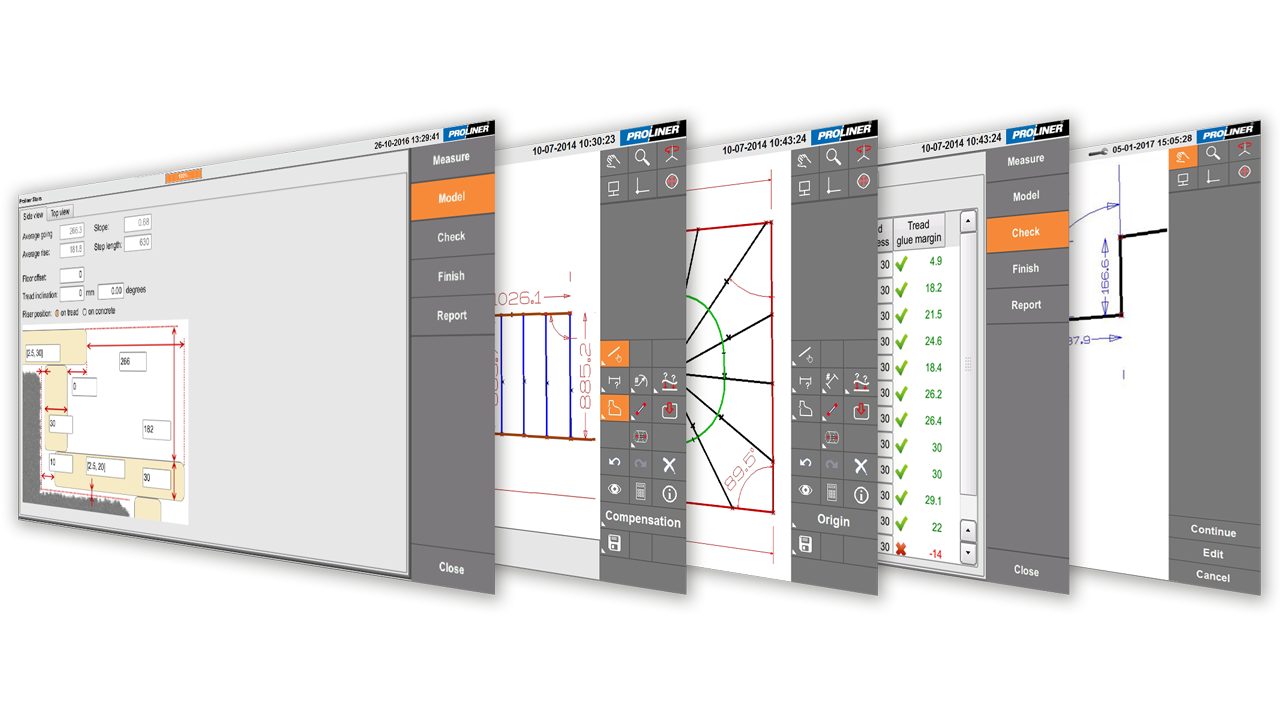

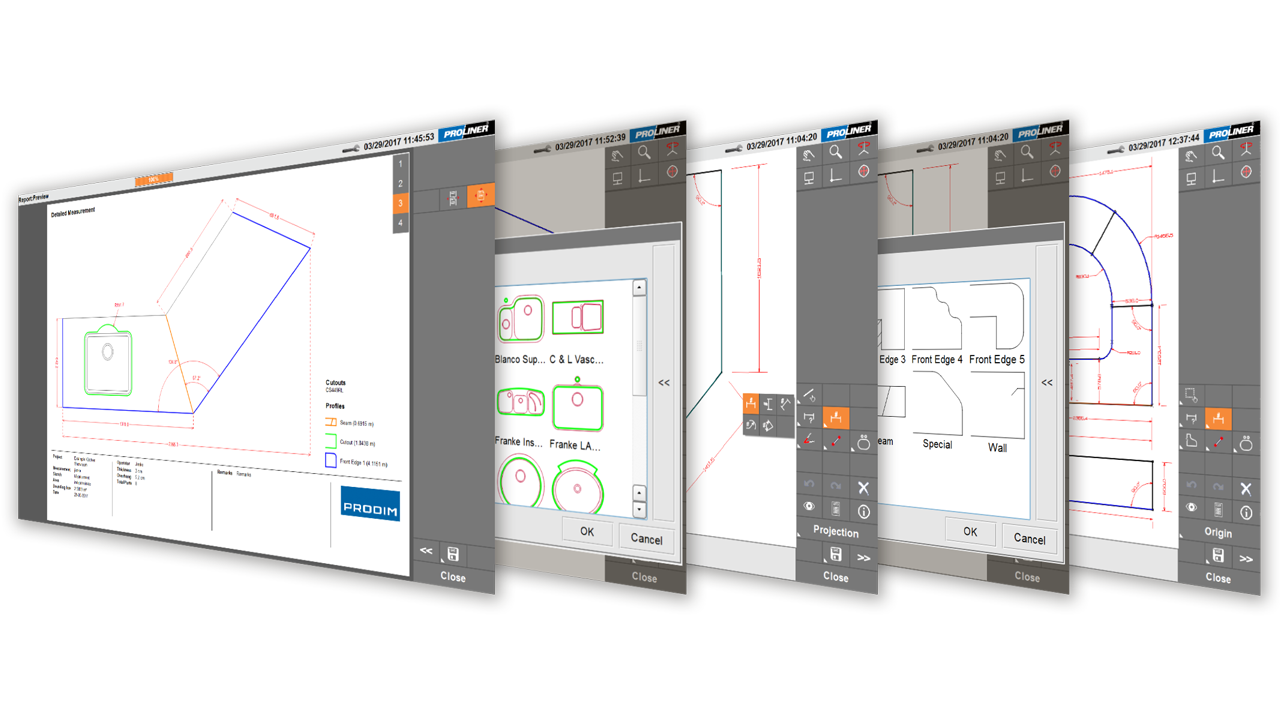

2D-3D digital templating using a line for pin-point accuracy and adaptability.

Prodim offers complete digital templating solutions for the stone industry. With the Proliner at the centre of each solution, Prodim provides the fastest, most accurate, reliable, flexible and durable digital templating tool in the market.

Used together with the self-developed Prodim Factory stone industry software, Prodim can offer any stone templater and fabricator a complete digital templating solution to help their business grow.

Become a Pro – Go digital – Get the Best!

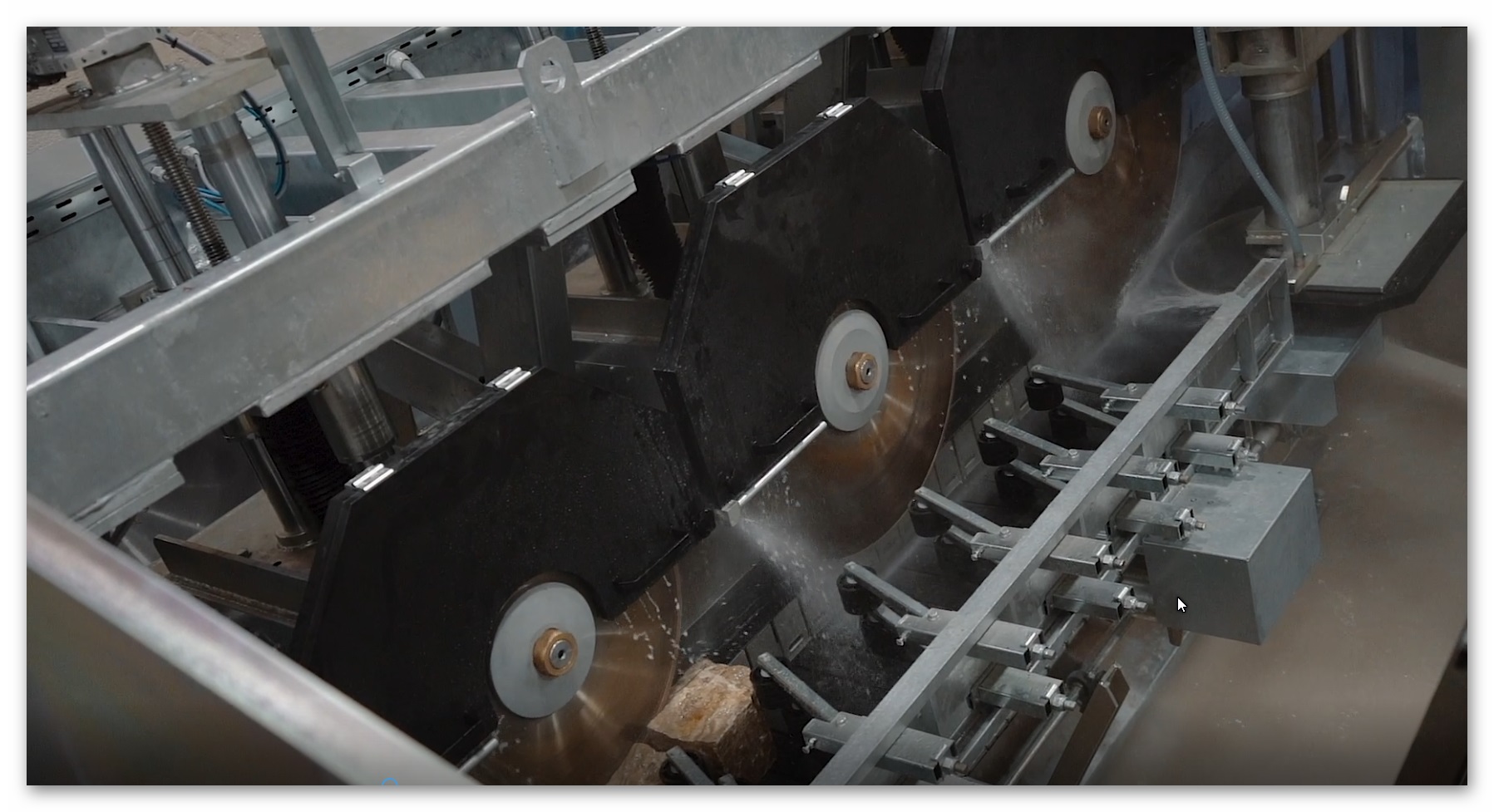

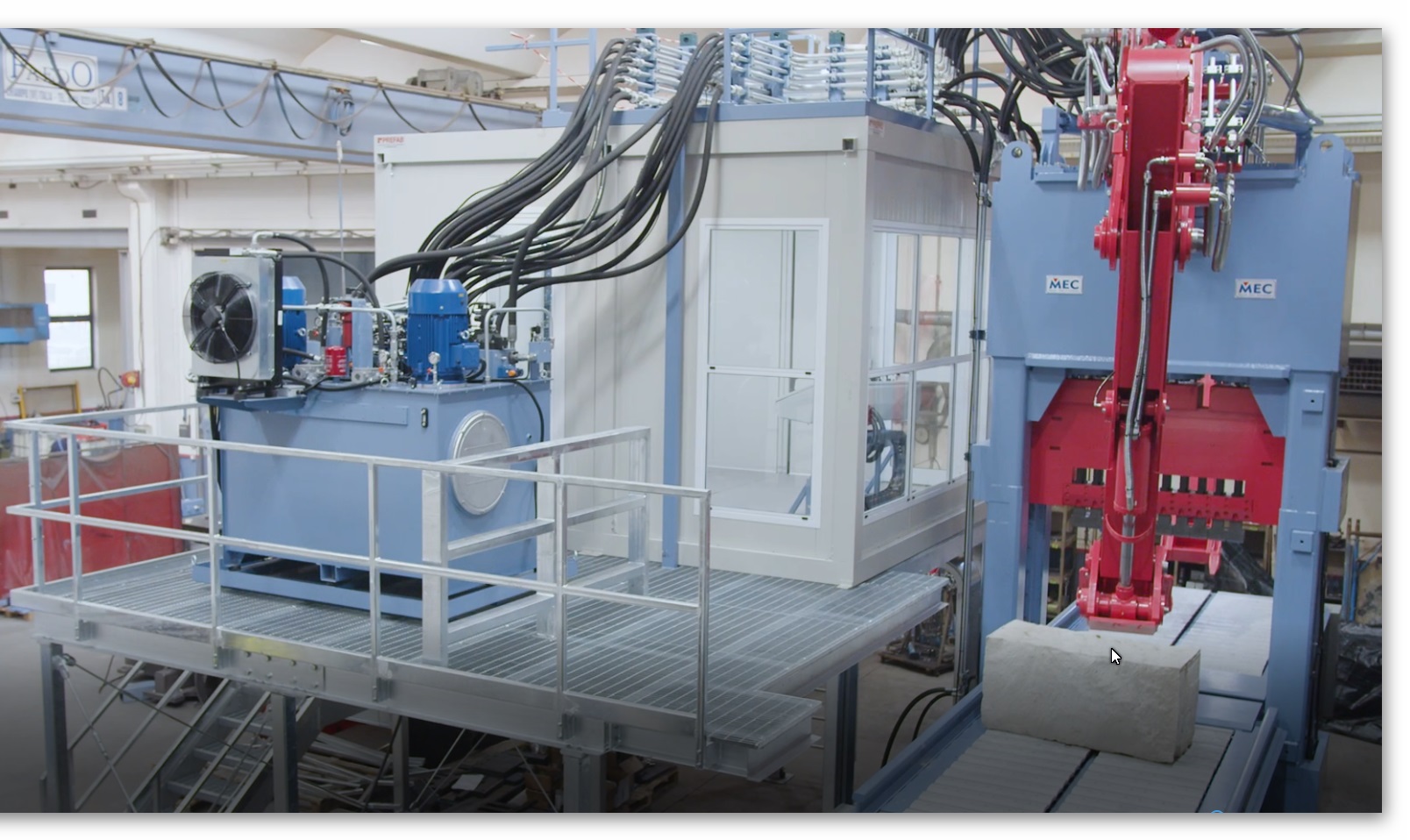

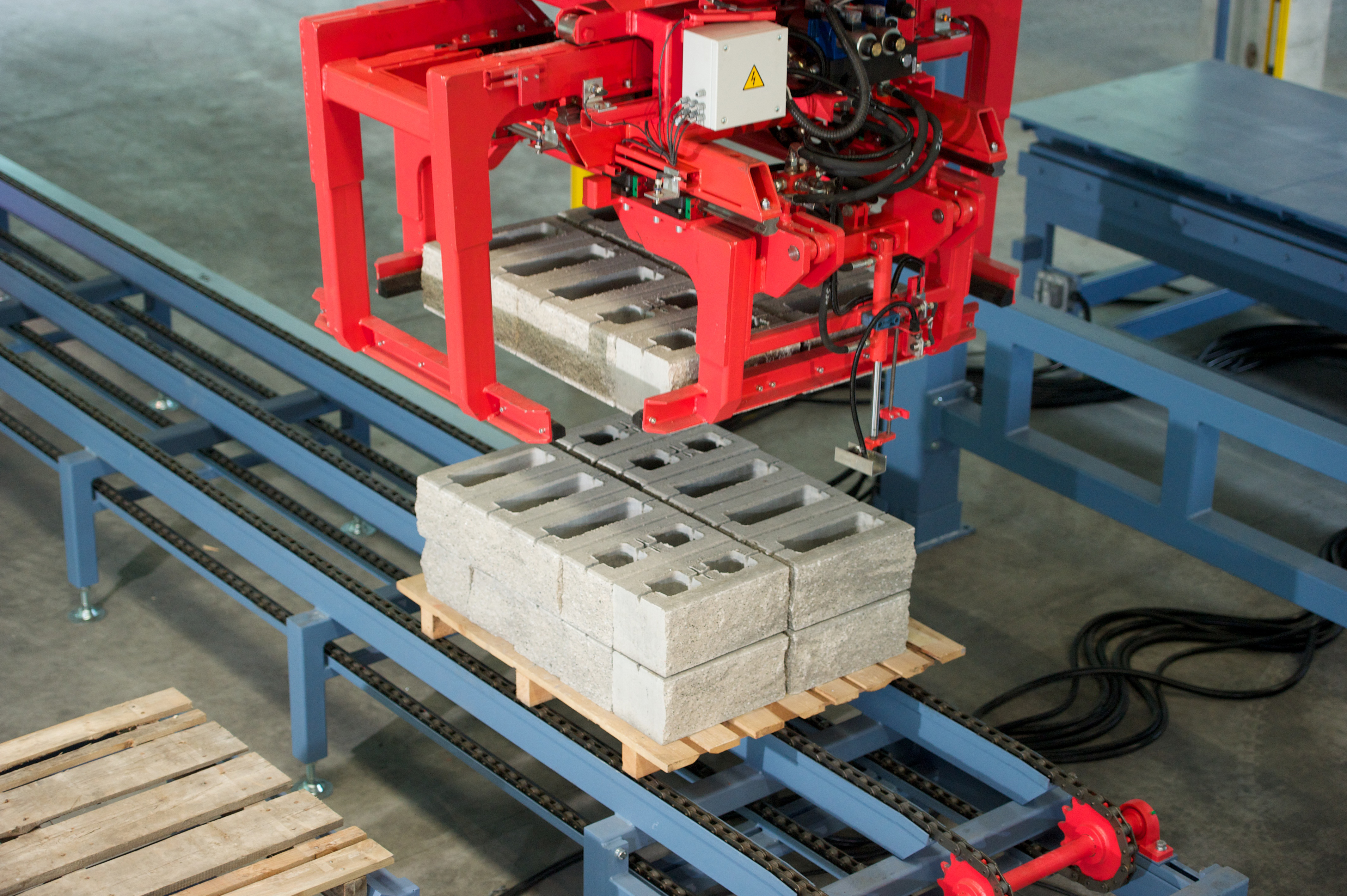

MEC is a leading company in stone and concrete splitting machines and lines, crushing machines and lines and thin veneer cutting machines.

Today, thanks to the know-how acquired, MEC is present in more than 70 countries.

MEC's range of stone splitting machines includes open-frame and closed-frame machines, also known as SPLITTER or CROPPING MACHINES, for splitting any type of natural stone.

Flexibility is their main characteristic: each of them can be set up and customized according to customer needs and integrated into complete lines.

MEC also designs and produces handling systems (conveyors, pushers, manipulators) to move the stone quickly, without any risk or fatigue for the operator.

MEC has an entire range of machines dedicated to finishing: horizontal or vertical pitching machines.

MEC also offers a series of Thin Veneer cutting machines FAST: conceived to split stones of different sizes with minimum thickness thanks to its in-line diamond blades. From the simple reduction of waste volume, to the recovery for road construction or street furniture, the crushers, the crushing lines and the hammer mills from MEC are a great opportunity for customers working with stone or concrete.

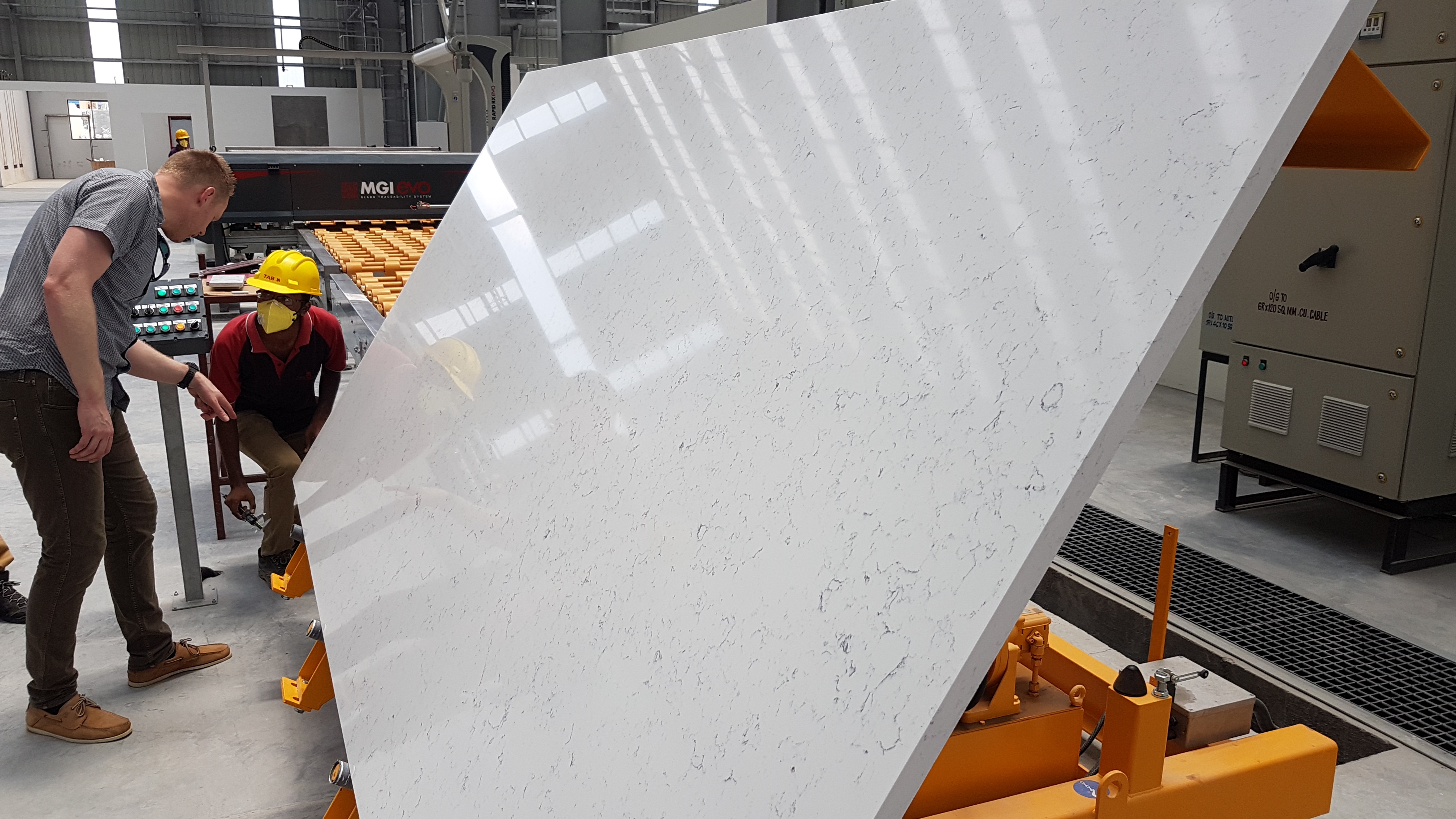

TAB INDIA is one of the largest and most innovative natural stone processors in the world. As a top brand in the natural stone industry, we offer an extraordinary selection of granite, marble, slate, quartzite, sandstone and limestone. Proprietary options, exotic colors, unlimited sizes and superior finishes have established us as an industry leader for both interior and exterior applications of natural stone. We are known around the world for our pro-granite campaign, our commitment to sustainability, our dedication to premium quality and the unique relationships we form with customers.

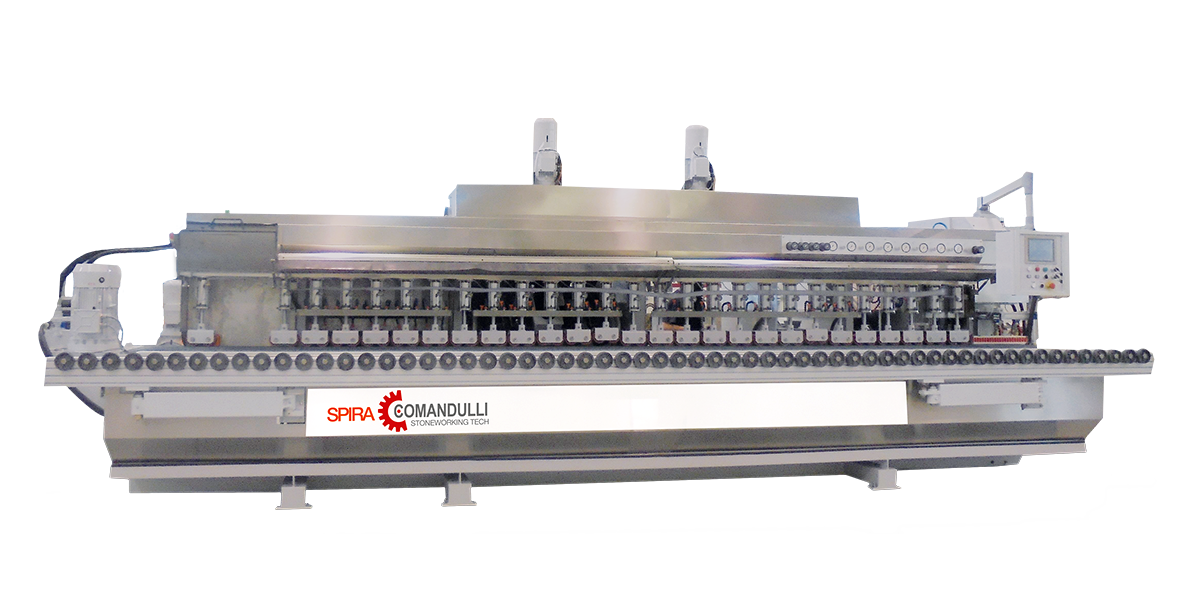

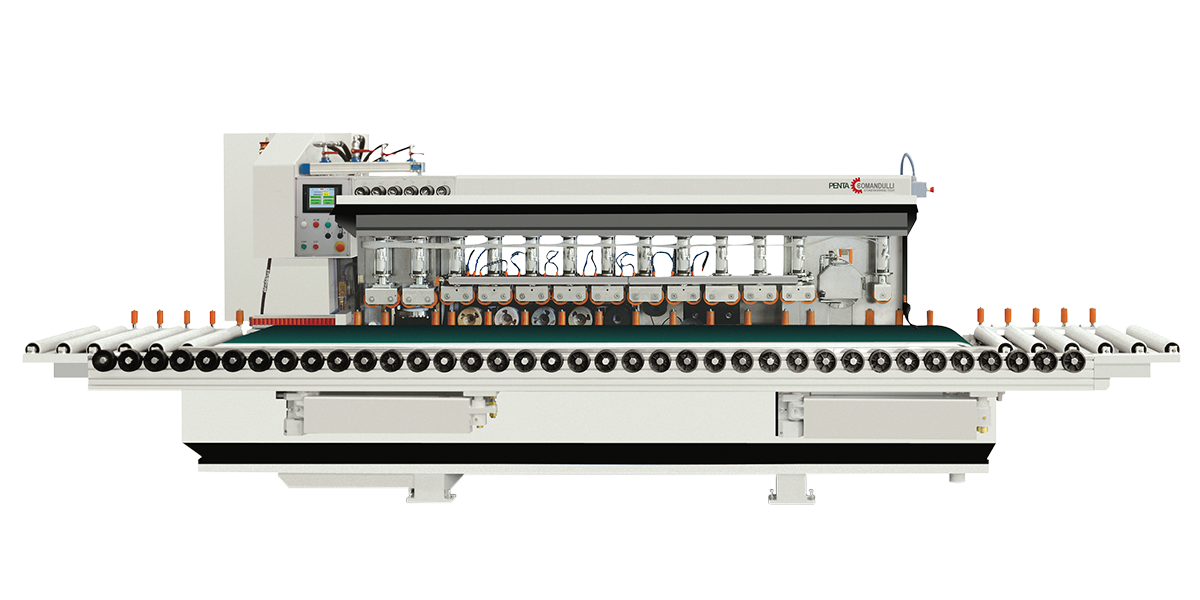

The UK supplier for all Comandulli machinery and equipment, part of LPE Group.

When you’re only ever going to be satisfied with leading production equipment in your workshop, you know you’ll only ever get it from Leading Production Equipment. The clue is in the name.